Features & Upgrades

WE ARE PROUD OF OUR PRODUCTS

Available Features

& Upgrades

Maine Radiator cores are hand crafted by experienced technicians. This allows for much greater process controls than mechanically assembled units. Tube holes in our fins are designed to fit the tubes tightly, thus achieving a much stronger, longer-lasting tube-to-fin bond that provides greater heat transfer. Tube holes on mechanically assembled cores are designed for quick assembly with a loose fit so that multiple tubes can be inserted in one step. We offer many design options, including full corner buildups for added strength to meet the rigorous demands of your industry.

ADVANTAGE OF OUR PRODUCTS

FEATURES

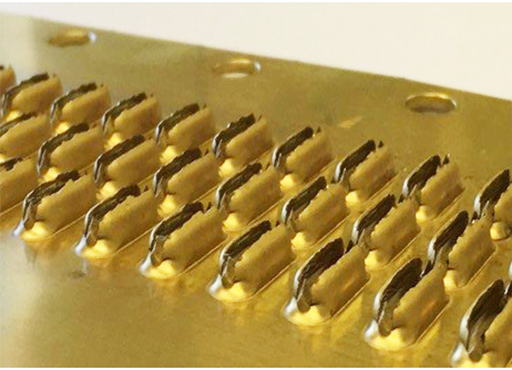

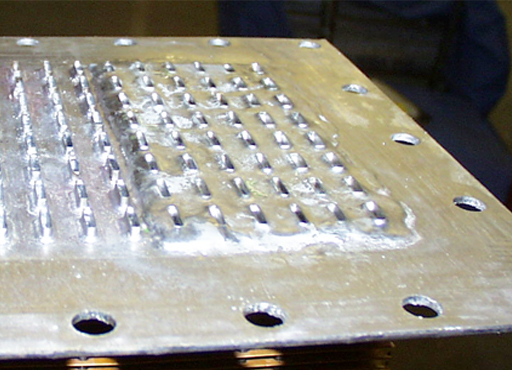

Heavier Brass Headers

We use only .064 and .125 thick brass headers on bolt-on cores. This is up to 28% heavier than industry standards. We offer Dished Headers for locomotive and other applications. Our .064 headers are pierced giving a full 7/32” tube to header support which increase tube to header strength and longevity.

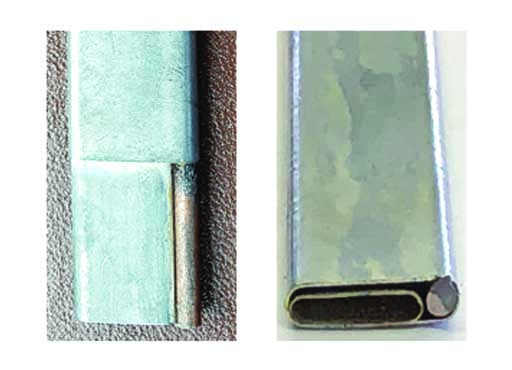

100% Welded Tubing

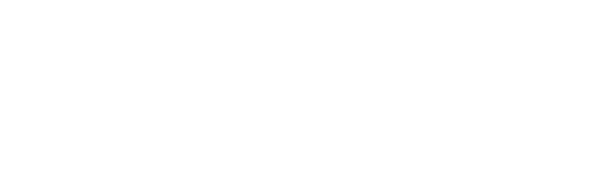

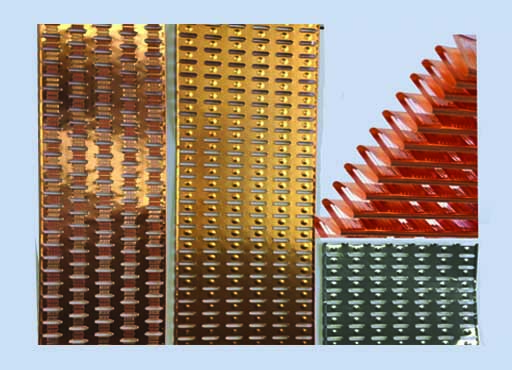

Heavy Cooling Fins

We offer both copper and steel fins that are up to 25% heavier than the industry standard. Heavier fins resist corrosion and provide a longer lasting tube-to fin bond and retain maximum heat transfer. Our industrial fins are designed with a hollow hem. The hem quadruples the core’s ability to withstand edge damage in abrasive environments and when cleaning the core. Solder Dipped Fins are also an option. Solder dipping provides extra protection in any high corrosion/abrasion application. We continue to build cores with Center Mounting Bars for older Caterpillar models.

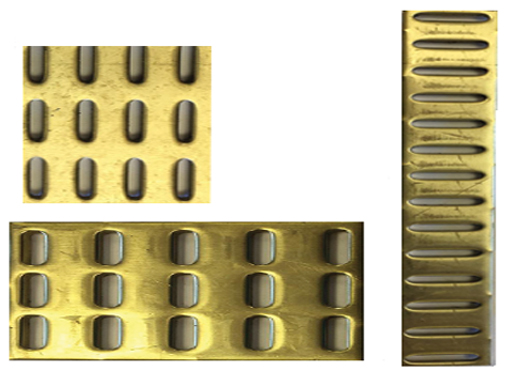

Tube To Header Reinforcement

Maine reinforces the corners on all truck and industrial cores, where most failures occur. We offer standard corner reinforcements, 1/8” thick corner reinforcements and 1/8” picture frame (all around) reinforcements. Again, resulting in longer life.

PTO / Crankbox Cores

Maine makes a fully functioning crankbox, retaining maximum radiator function.

Clog - Free Core Design

Maine also offers Inline Cores for dirty, dusty applications where radiator clogging is a problem. Combined with a non-louvered fin, this design “breaths” better and is easily cleaned.

BOLT-ON HEADER

TUBE GUARDS

pto

DISHED HEADER

tubes

CORNER BUILDUP

TYPES OF FINS

REINFORCEMENTS

Proudly manufactured in the U.S.A.

Phone

207-784-0189

800-341-0230

sales@maineradiator.com

Address

14 Forrestal St.

Lewiston, ME 04240

HOURS

Monday - Friday

8:00am - 5:00pm (EST)